To reduce the raw material to a fine powder, a pulverizer such as the Hammer Mill Series is utilized. It complies with the GMP Standard standards. This type of pulverizer is used to turn large materials into fine powder. The pharmaceutical, chemical, food, powder metallurgy, cosmetic, dyeing, and other industries may all make extensive use of it.

Large materials are ground into tiny granules or fine powder using a hammer mill equipment. Several different types of raw materials are mixed into an even mixture using the material that is fed on. The positive and negative rotary shafts are the two that exist. The shaft connection that is attached to the reducer drives the positive shaft. The negative shaft rotates in the interim in accordance. The drum and the hoop, which are joined by belts, are mounted to the shafts as a single unit. The hoop and the drum will move in cycles to mix the materials within when the shafts revolve.

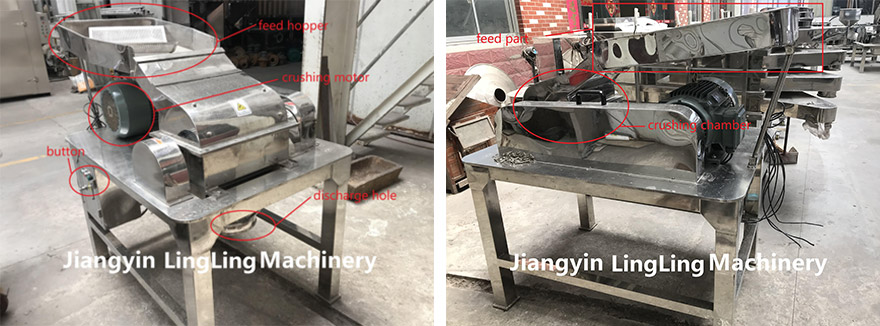

(1) The material drum, base, hoop, and transmission system make up the majority of a hammer mill machine. The motor, reducer, shaft contactor, and positive and negative shafts are all parts of the transmission system. The hoop has the drum fastened to it at an angle to the horizontal line. This guarantees the uniform blending result.

(2) The hammer mill drum is simply removed from the hoop after it has been fastened to it. Thus, one or two drums are often ready for replacement.

(3) The machine's advantages are its tiny holding space, attractive look, simple operation, quick cleaning, and compact structure.

| Model | GFSJ-8 | GFSJ-16 | GFSJ-32 |

| Capacity (kg/h) | 10-100 | 100-300 | 300-800 |

| Fineness (mm) | 20-120 | ||

| Motor power (kw) | 3 | 7.5 | 11 |

| Spindle speed (rpm) | 2350-4360 | 1000-2400-4400 | |

| Overall size (mm) | 1050*600*1600 | 1100*860*1520 | 1280*950*1600 |

| Weight (kg) | 150 | 300 | 450 |