A fine powder is produced by grinding the raw material in a LINGLING Spices Hammer Mill. It conforms to GMP requirements. This kind of pulverizer is used to grind up big objects into a fine powder. It may be used in many different fields, including the dyeing, powder metallurgy, chemical, and culinary sectors.

LINGLING Seasonings The big-size material is ground into small granules or fine powder using a hammer mill. The feedstock is used to blend a range of fundamental elements uniformly. There are rotational shafts that are positive and negative. The positive shaft is driven by the shaft connector, which is fastened to the reducer. Meanwhile, the negative shaft is turning. The drum and the hoop are attached to the shafts as one unit and are connected by belts. As the shafts rotate, the hoop and drum will oscillate, blending the internal elements.

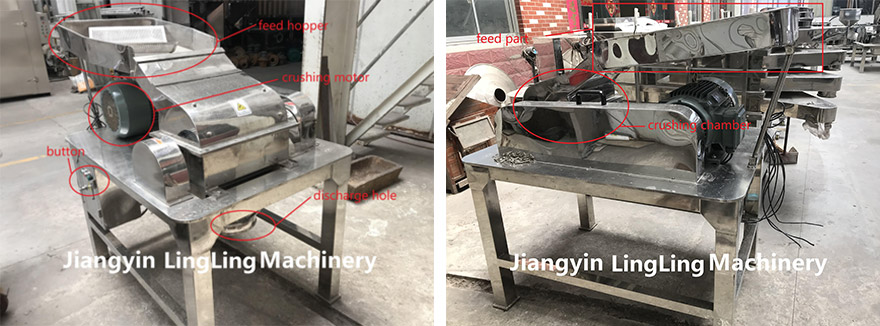

LINGLING Seasonings The material drum, base, hoop, and transmission system make up the majority of a hammer mill machine. The transmission system is made up of the motor, reducer, shaft contactor, positive and negative shafts, and others. The drum is fixed to the hoop and inclined in the direction of the horizontal axis. This ensures a fair mixing outcome.

| Model | GFSJ-8 | GFSJ-16 | GFSJ-32 |

| Capacity (kg/h) | 10-100 | 100-300 | 300-800 |

| Fineness (mm) | 20-120 | ||

| Motor power (kw) | 3 | 7.5 | 11 |

| Spindle speed (rpm) | 2350-4360 | 1000-2400-4400 | |

| Overall size (mm) | 1050*600*1600 | 1100*860*1520 | 1280*950*1600 |

| Weight (kg) | 150 | 300 | 450 |