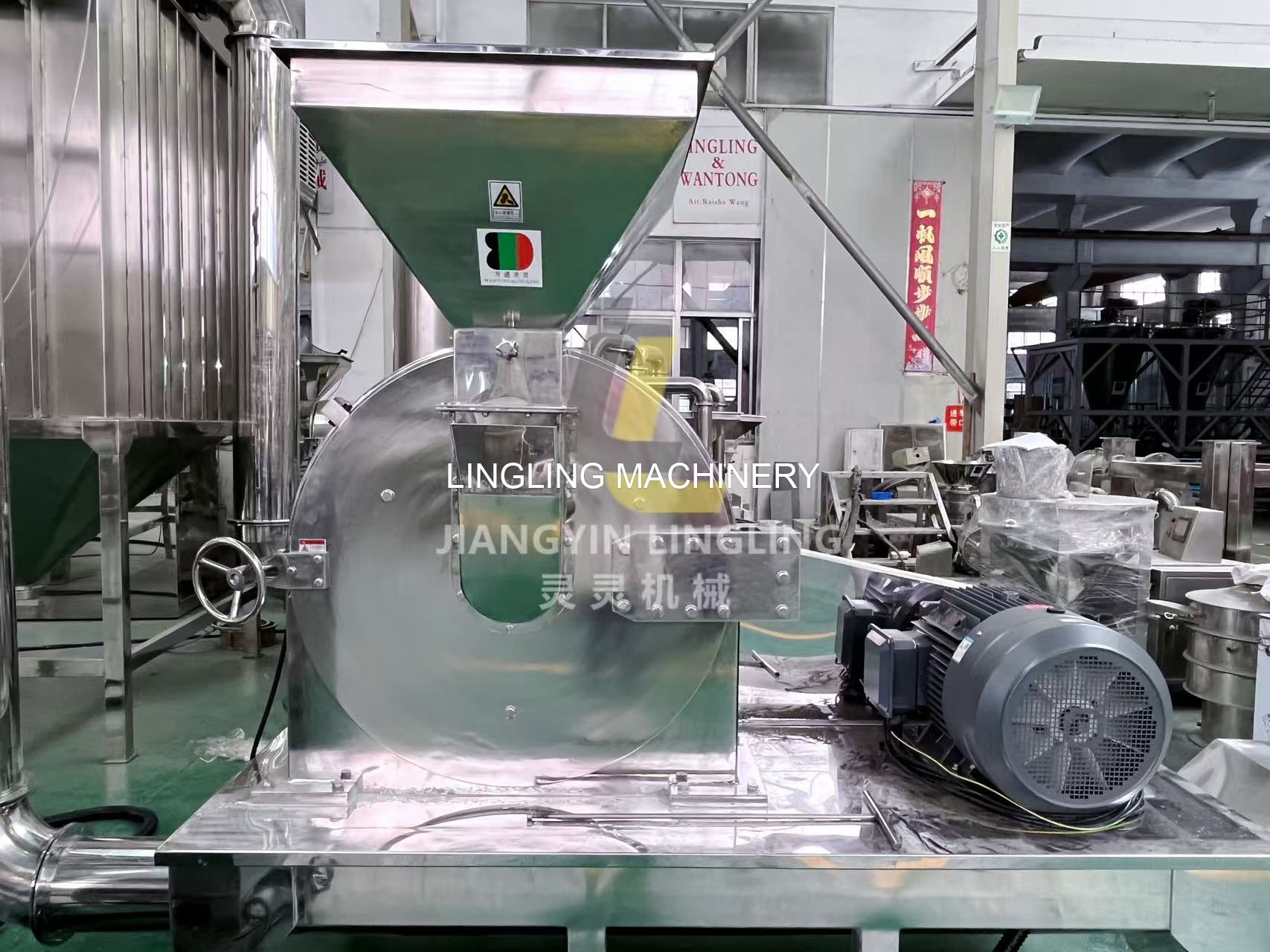

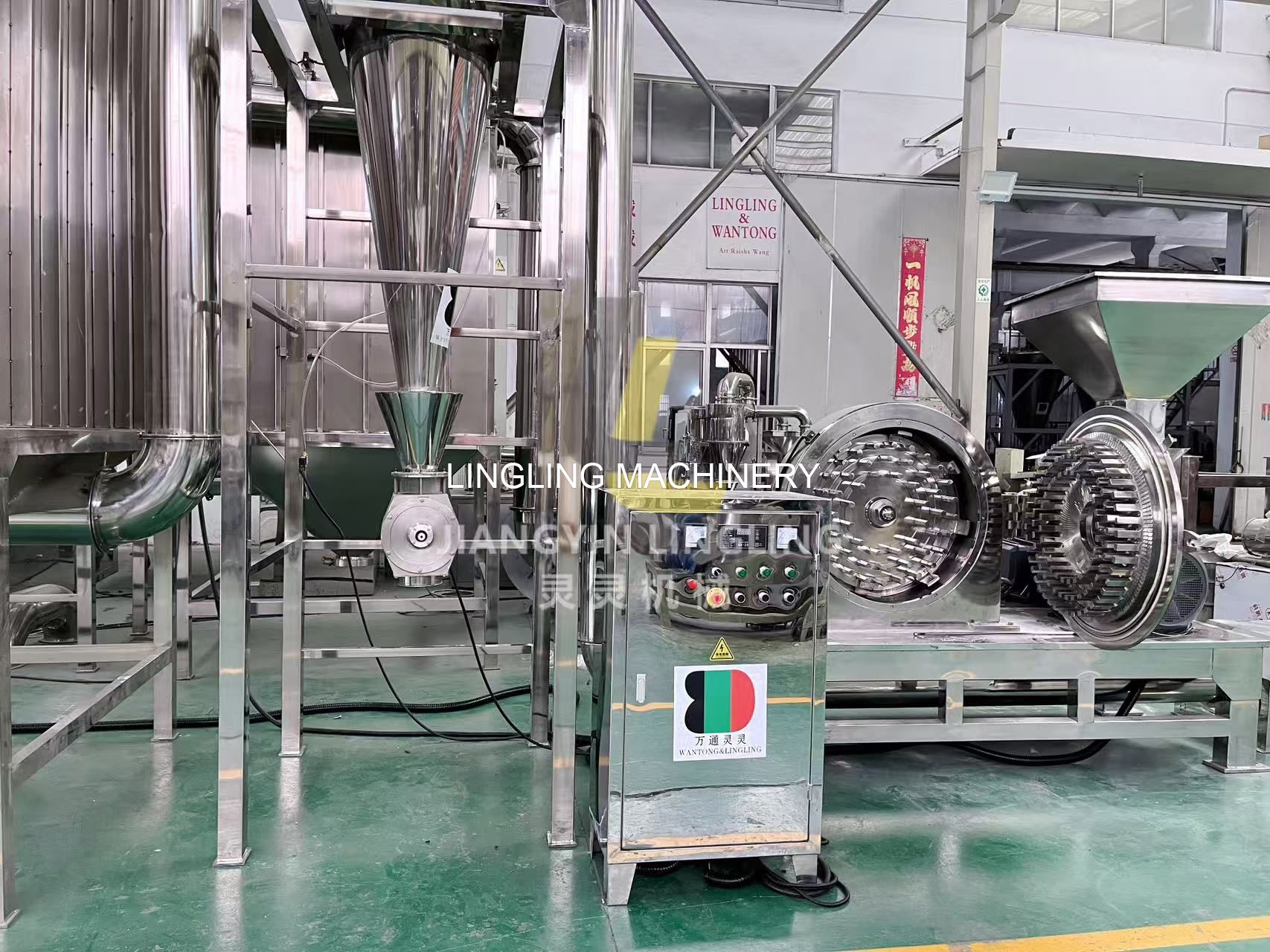

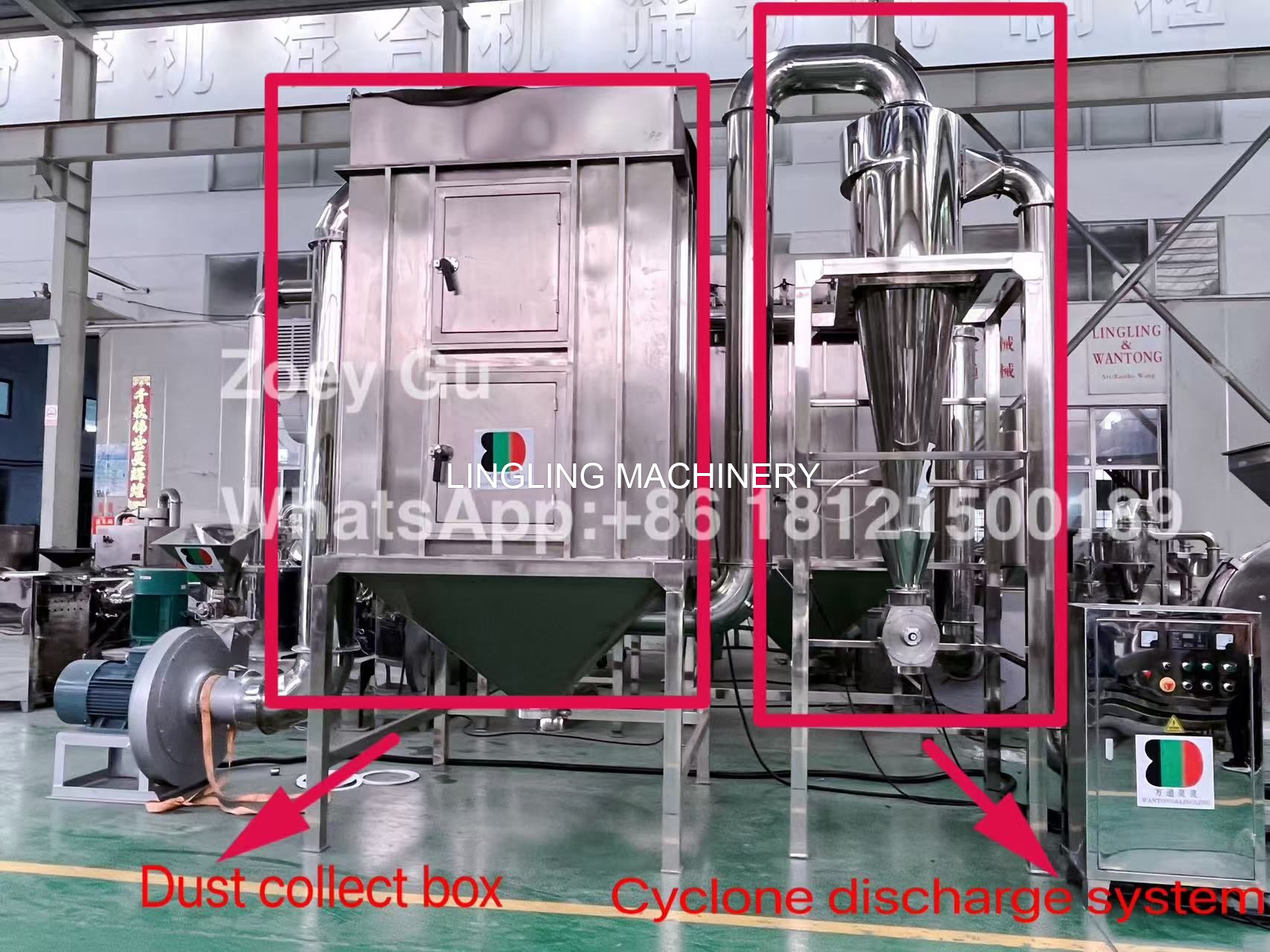

This WFC Complete Impact Pulverizer machine is mainly used in chemical industry, medicine (TCM), food, spices, resin powder, besmear powder etc, sex material and high temperature resistant material, crushing and dust collection as a whole is a new generation crushing equipment.

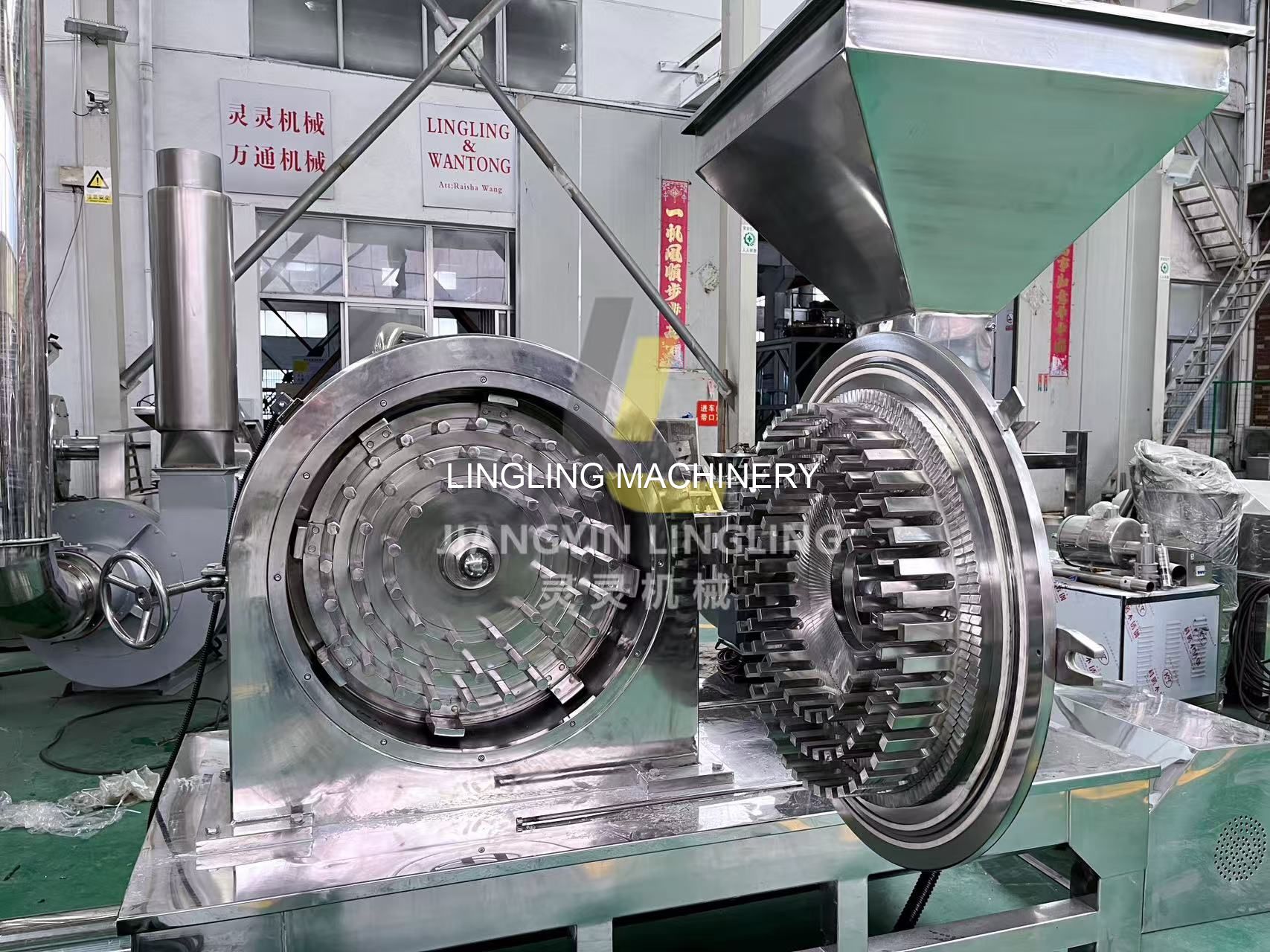

This Complete sugar powder grinder adopts the tooth disc high-speed rotating knife, the fixed knife impact and shear grinding to crush. The crushing effect is good, the heat of crushing chamber and finished product outflow together from sieve by strong airflow which produced when crushing, crushing fineness can be decided by different sieves.

None

| Model | Capacity (kg) | Feed size(mm) | Output size(mesh) | Total power(kw) | Main speed(r/min) | Dimension(mm) | Weight (kg) |

| WF-30C | 50-300 | <10 | 12-120 | 11.75 | ~3800 | 6000*1200*2900 | 700 |

| WF-40C | 80-400 | <12 | 13.75 | ~3400 | 6300*1300*2900 | 1000 | |

| WF-50C | 100-500 | <12 | 17.25 | ~2900 | 7000*1500*2900 | 1200 | |

| WF-60C | 300-800 | <15 | 33.75 | ~2400 | 7500*1500*3650 | 1500 | |

| WF-80C | 400-1500 | <15 | 60.1 | ~2200 | 8400*2500*4850 | 2000 |