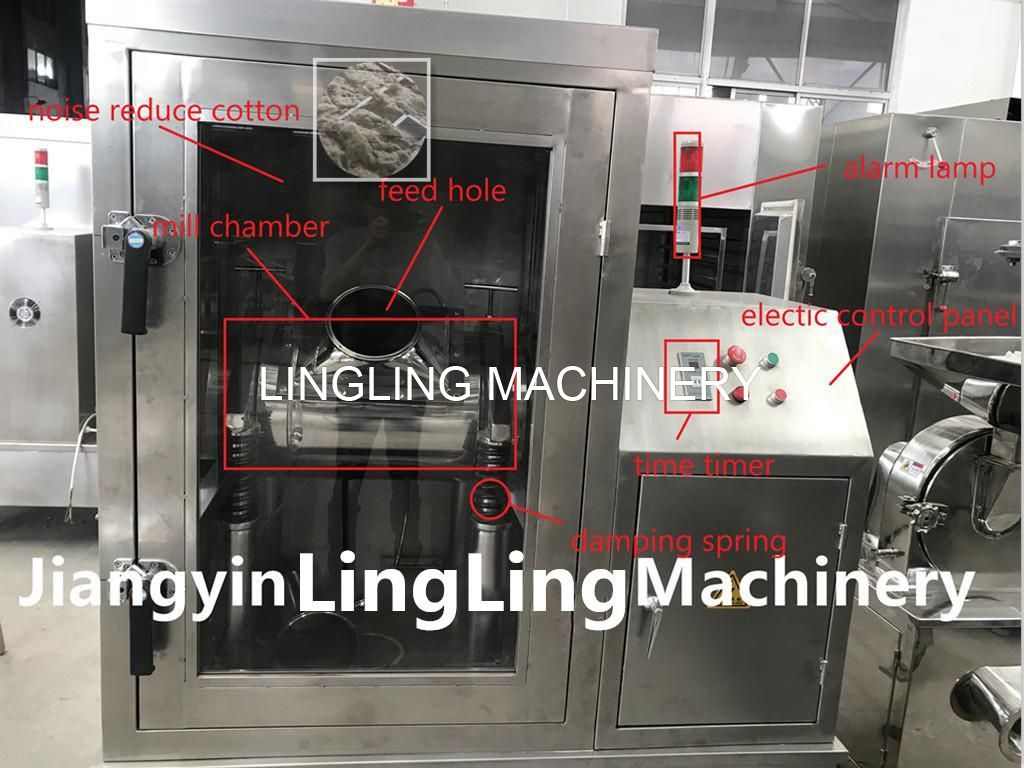

The machine in question is a horizontal vibrating pulverizer. It's outfitted with a cooling water device, which serves the crucial function of regulating the temperature within the chamber. The process begins as material is introduced from the hopper and directed into the grinding chamber. Here, the machine capitalizes on the forceful impacts that occur between the grinding stick and the material to carry out the pulverization process effectively.

The horizontal vibrating pulverizer is a marvel. Optimized vibrations make its medium act powerfully, crushing materials at high speed. With perks like adjustable temps, low noise via the noise reducer, a disinfection setup, water cooling for better performance, and an easy time control, you can set grinding time for your desired powder fineness.

This horizontal vibration mill functions in a straightforward yet efficient manner. Material is funneled into the crushing chamber from the hopper. Once there, the vibrations prompt the grinding rods to smash against the material, pulverizing it. Equipped with a water cooling unit, it keeps the chamber temperature in check. Built to “GMP” standards, its stainless steel construction ensures durability. Operating fully sealed, it curtails dust dispersion, averting any environmental pollution.

| MODEL | 20 | 50 | 100 |

| Load volume(L) | 20 | 50 | 100 |

| Capacity(kg/batch) | 2-10 | 10-30 | 20-60 |

| Final powder fineness | 200-3000mesh | ||

| Cooling method | Water cooling | ||

| Power(kw) | 2 | 7.5 | 11 |

| Overall size(mm) (L×W×H) | 1250×900×1400 | 2100×1000×1600 | 2850×1500×1800 |

| Weight(kg) | 500 | 950 | 1500 |