The machine is effective for any fiber, high toughness, high hardness or a certain degree of water content of the material can be effectively crushed, especially for Chinese medicine cell wall and other purposes designed to improve the bioavailability of drugs and the use of conventional methods can not meet the requirements Fineness of the material.

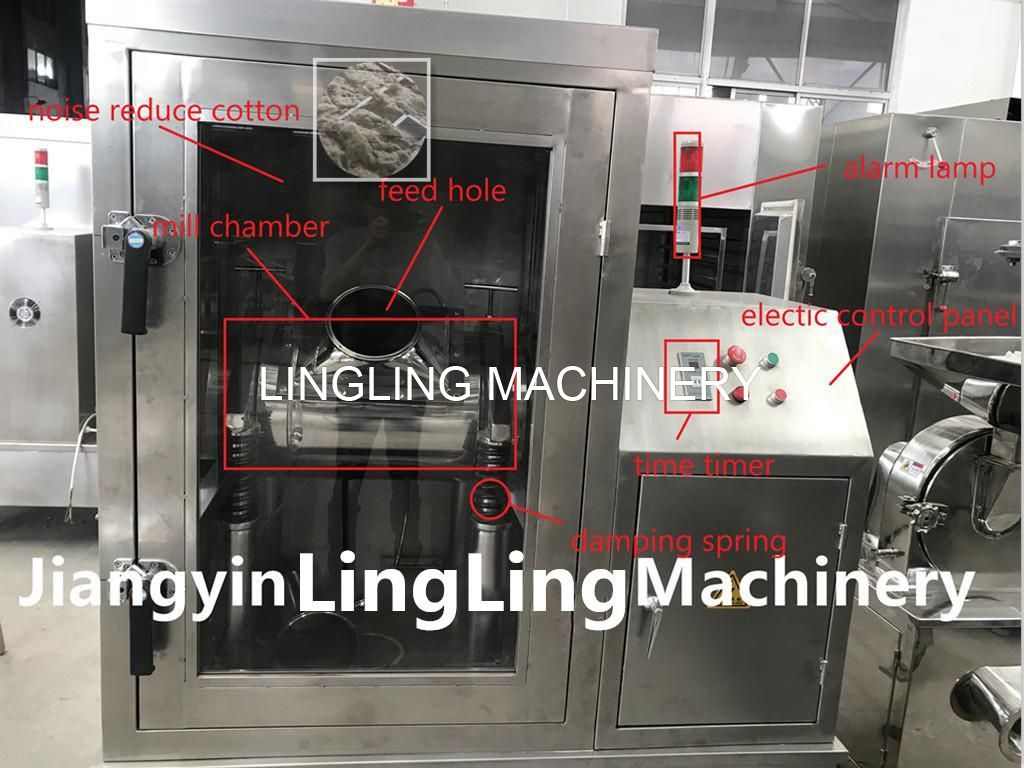

The machine is designed to leverage optimized vibration parameters, which cause the medium within it to not only vibrate and generate shock waves but also rotate and revolve simultaneously. This dual action subjects the objects being processed to both direct impact and high-intensity cutting forces, enabling high-speed and high-energy crushing. It stands out for its high efficiency, controllable pollution levels, and adjustable crushing temperature. What's more, it can precisely carry out mixing, compounding, and coating operations involving two or more types of materials. You have full control over the fineness of the final powder by setting the vibration grinding time. For an ultra-fine powder result, simply set the time to 45 minutes or longer. If a less fine powder suffices for your needs, a setting of 10 minutes or less will do the trick. 1. Exceptionally low noise levels are achieved as the noise reducer chamber encloses the main grinding component, effectively muffling any excessive sound. 2. It features a disinfection system, adding an extra layer of hygiene and safety during the operation. 3. Equipped with a water cooler, the machine's performance and efficiency are significantly enhanced, allowing for smoother and more productive runs. 4. The time control system simplifies the operation process, making it convenient and user-friendly for anyone to manage the grinding duration with ease.

This machine is a horizontal vibration mill. The material is fed into the crushing chamber from the hopper. Once inside, the vibration makes the grinding rods within the chamber collide with the material, grinding and crushing it. The machine comes equipped with a water cooling device, which effectively controls the temperature of the crushing chamber. Designed in line with the "GMP" standard, it is fabricated using stainless steel. During operation, the equipment operates in a fully sealed state, preventing any dust from flying about and eliminating environmental pollution.

| MODEL | 20 | 50 | 100 |

| Load volume(L) | 20 | 50 | 100 |

| Capacity(kg/batch) | 2-10 | 10-30 | 20-60 |

| Final powder fineness | 200-3000mesh | ||

| Cooling method | Water cooling | ||

| Power(kw) | 2 | 7.5 | 11 |

| Overall size(mm) (L×W×H) | 1250×900×1400 | 2100×1000×1600 | 2850×1500×1800 |

| Weight(kg) | 500 | 950 | 1500 |